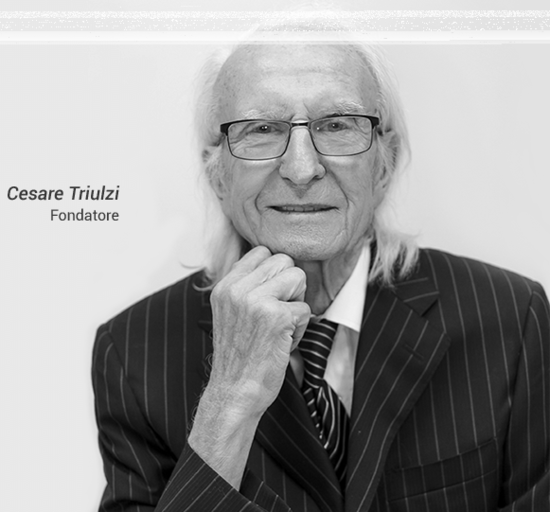

A story between creativity and technology

Foundation

After initial work experience, Cesare Triulzi decided on his entrepreneurial destiny with the 500 thousand lire received from his father. In 1952 in Bovisio Masciago he founded Triulzi, the first company in Italy that handcrafts automatic washing machines. The glass washers and dryers quickly became popular at all the glassworks, from north to south. The workshop began to grow, thanks also to the first orders received from abroad.

Foundation

The reputation of pioneer and inventor of glass washing and drying machines is spreading across Europe and the world. Mr. Cesare personally participates in the most important world fairs, bringing, first among all, the "made in Italy" to the international markets. Milan, Paris, Moscow, Washington, Düsseldorf... everywhere, Triulzi machines collect interest and appreciation . Requests come from the market to expand the range of products, introducing new functions and automatic operations.

Widening

Production expands and the company moves to Limbiate, in the current, larger and more functional spaces. New machines, which become reference points, are designed and built, such as the mirror conveyor. And once again, Triulzi is the first in Italy to manufacture the laminating machine for glass: a concentrate of technology, innovation and reliability that travels around the world and helps open up new markets.

Acknowledgments

These are years of great satisfaction for Triulzi. The company is now structured and present with its products all over the world; the network of agents and representatives is also consolidated. Mr. Cesare has been rewarded for his efforts and commitment over the years by receiving an award from the Milan Chamber of Commerce: the gold medal for merits related to the export of "made in Italy" products to the world. An official recognition that confirms the company's creative and technological attitude. New models are made: Toscana, Mini and Jumbo.

Consolidation

These are years of transformation and new entries into the company. The new Triulzi generation enters the team with enthusiasm, ideas and skills, helping to optimize the organizational structure, increasingly projected towards foreign markets. In the meantime, Mr. Cesare receives two honorary certificates in the United States and France. But nobody rests on their laurels. In fact, to meet the demands of the photovoltaic sector, machines are made for solar panels (and, subsequently, a real dedicated division). The model for the automatic process of etched glass is also built.

Innovation

Always attentive to the evolution of the markets and customer problems, Triulzi manufactures the talc machine for the automotive sector, one of the most demanding in terms of both performance and quality. But attention also shifts to other application sectors such as construction and interiors. Meanwhile, the participation in international fairs continues, from Russia to China, from Brazil to India: the company is looked upon with respect by the industry giants.

Everyday

Thanks to the unchanged pioneering spirit and to the inexhaustible creativity that have accompanied Triulzi by birth, we constantly bring innovative solutions to the market, like the ultrasonic bath, which uses the efficiency of nanotechnologies for a washing perfection never achieved so far, and the washing machine for curved glass. This confirms that the new generation at the helm of Triulzi inherited the best by those who founded it more than sixty years ago.

Our tomorrow is today

Innovation is in our DNA. And our gaze is always turned to the new challenges of the market. We are already working on projects that will soon become standard worldwide. The future has just begun.